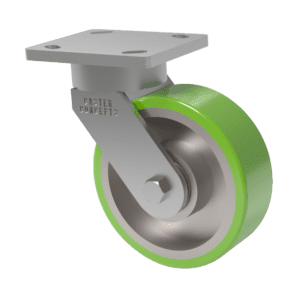

The ErgoXcel is a caster wheel made of an aluminum core with a full round or balloon tread polyurethane. The rounded tread helps provide ergonomic benefits when used on material handling carts.

ErgoXcell rounded wheel

Standard “flat” wheel

A flat-faced standard wheel means a wider contact patch touching the ground. ErgoXcel wheels have a rounded edge and a narrower patch that the cart moves on, which means less friction with the surface. ErgoXcel wheels come with precision ball bearings and are available for either a ½” or ¾” axle. A sealed precision ball bearing makes the wheel maintenance free. So, the 37,55, and 57 rigs equipped with our ErgoXcell wheels become maintenance-free casters.

All of our wheels are processed through our hot cast polyurethane entity, Reaction Industries, located under the same roof as Caster Concepts. This in-house processing of our wheels allows us to maintain industry-best lead times on casters and wheels. The ErgoXcel uses a core with a locking mechanism that works in conjunction with the bond that gets established in our normal wheel molding process. Typically, you would look at the tread on these wheels and think it is a thick tread polyurethane, but it is not. The thin tread polyurethane makeup helps keep costs down while maximizing the ergonomic benefits of the rounded finish.

These wheels can come in various sizes ranging from 4″ – 8″ in diameter, with the width of these wheels being 2″. While we can make a round tread on any wheel, the ErgoXcel is an ergonomic wheel that you shouldn’t use on carts weighing over 2,000 lbs. They are best suited for applications ranging from 800-1,200 lbs.

The PTMEG tread material also makes these ErgoXcel wheels deflect debris and maintain an ergonomic advantage even when dirty/abusive environments are present. The Ergo Tread (PTMEG) has excellent rebound, so if your wheels begin to flat spot, please check out our blog on what polyurethane you should use if you need help. A wheel that has a good rebound means it can roll itself out and get back to the wheel’s original state.

Polytetramethylene Ether Glycol (PTMEG) is the premier polyether polyol used worldwide to manufacture high-performance polyurethane elastomers. |

PTMEG is known for its many performance attributes and processing advantages. These wheels are popular within the Automotive and Agricultural industries and countless others when ergonomics are needed to either be improved upon to prevent an injury or used to create a tow behind a cart that extends the battery life of an AGV (Automated Guided Vehicle).

ErgoXcel wheels are versatile and utilized in many different caster rigs and sizes. Facilities with multiple weight ranges can still use these wheels as a company standard while maintaining safe push/pull forces on manual carts.

Moving to a “standard” caster at your facilities helps reduce the number of SKU numbers floating around the shop floor. It also relieves pressure on the maintenance teams responsible for tracking down the correct caster to install or fix what’s in front of them. The standardization of a caster maintains one height for all carts and makes it easier for engineers to design improvements. This also eliminates the worry that a new cart will not pass ergonomic safety standards — knowing that if you maintain the cart’s total weight, the caster will still pass based on previous testing. This is not always an option for today’s ever-changing manufacturing landscape, but your team will save time and energy even if you can standardize one work cell or department.