PPE (Personal Protective Equipment) is now known more than ever due to what has happened worldwide over the last couple of years. In manufacturing specifically, things like earplugs, safety glasses, bump caps (or hard hats), and steel-toe shoes have been used for years and years to help ensure operators make it home as safely as when they arrived to work.

I will share some data and walk you through some first-hand examples of why heavy-duty casters are no different in the PPE category when you have hand-moved carts/dollies at your facility.

I will share some data and walk you through some first-hand examples of why heavy-duty casters are no different in the PPE category when you have hand-moved carts/dollies at your facility.

EHS professionals are always looking for ways to help keep everyone safe while being able to execute the day-to-day requirements at a high level. Injuries resulting in gruesome outcomes are typically priority #1 when creating a safety budget. Whether that be a finger that gets cut off, a limb, or anything else in the extreme, they get treated first and foremost.

There is nothing wrong with that. However, did you know that the number one leading cause of workplace injuries is an overexertion injury? Repetitive motions usually cause overexertion injuries and can include any of the following: lifting, pushing, pulling, carrying, or holding.

While that doesn’t all relate to casters directly, the two that stick out are Pushing and Pulling. Depending on your workstation setup and size, operators can be stuck pushing carts over thousands of feet per day. And these overexertion injuries typically do not happen at one specific push

Twergo Xtreme

and pull. They are slow to develop and tend to be repetitive back or shoulder injuries from constantly moving around carts.

The first couple of times before the first break of the day, I am sure there are no problems with the carts. After lunch, when the same operators have had 6 hours of moving the same cart around, that is when fatigue and these overexertion injuries shine — Being able to work a blue-collar job for 35 years should not result in back injuries that don’t allow you to hold or play with your grandkids.

Being able to safely send someone home at the end of each shift is a great goal, and I want to challenge you to send your longest-tenured employee into retirement without costing them a back or a shoulder.

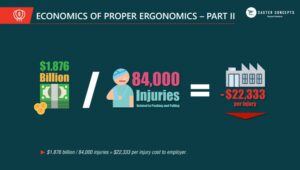

| OVEREXERTION INJURIES COST $13.4 BILLION YEARLY (1) | 14% OF WMSD INJURIES INVOLVE PUSHING/PULLING (1) | THAT EQUATES TO $1.876 BILLION PER YEAR |

1.876 Billion Dollars. Wow, that is a significant number… and the estimated cost is directly related to pushing and pulling injuries. Since roughly 84,000 people are hurt yearly due to this overexertion, it costs about $22,333 per injury.

1.876 Billion Dollars. Wow, that is a significant number… and the estimated cost is directly related to pushing and pulling injuries. Since roughly 84,000 people are hurt yearly due to this overexertion, it costs about $22,333 per injury.

If you have never thought of casters as a way to help make operators safe, you might not have considered using an ergonomic caster versus the cheapest one you can get your hands on to reduce the chance of injuries.

While OSHA does not currently have push/pull standards, they do have suggestions to assist.

For more information on push force and how to calculate, please watch this video ( Push/Pull Test Video 2022 | Caster Concepts – YouTube)

Doing safety walks in plants has allowed me to see manufacturing sites from vastly different industries, including Automotive, Agriculture, Steel Mills, Food, and Aviation. One common theme I always come away with is: the firsthand operators moving the carts and dollies all day long are typically not acknowledged by management until someone has already gotten hurt.

Casters do not have to be reactionary item that gets upgraded after someone has been severely injured for the rest of their life. If you are not sure how to start in your progress to making carts and dollies safe, reach out and give me a call! (517-680-7969). I am typically found in the Midwest with our customers, but I am always happy to help get you started in the right direction and point you to the correct rep in your area if needed.

References

National Research Council and the Institute of Medicine (2001). Musculoskeletal disorders and the workplace: low back and upper extremities. Panel on Musculoskeletal Disorders and the Workplace.(As cited in Centers for Disease Control and Prevention. Work-Related Musculoskeletal Disorders & Ergonomics).

https://www.nap.edu/read/10032/chapter/1

EHS Material Handling: The Secret to Reducing Workplace Injuries and Expenses.

2016.

https://www.ehstoday.com/safety/material-handling-secret-reducing-workplace-injuries-and-expenses

Liberty Mutual Manual Materials Handling Tables