Updated 10/12/2023

That boom you hear isn’t a jet plane lifting off; it’s the tugger cart with five empty carts trundling by on the plant floor.

Noise from carts has always been a safety and health hazard. Controlling noise pollution is critical to maintaining a safe and healthy workplace. It’s very dangerous if employees can’t hear co-workers or their surroundings. Additionally, employees exposed to excessive noise can suffer long-term hearing loss.

Many expensive design and retrofit options exist to curtail cart noise. However, affordable solutions to reduce delivery cart noise work very well and won’t cause budget overruns.

Below, I’d like to outline five budget-friendly solutions that substantially reduce pollution from moving carts.

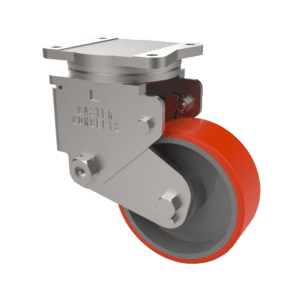

1. Polyurethane wheels: Harder wheels create more sound to vibrate from the floor through the wheel assembly and into the cart. Poly wheel material should be firm enough to support the load without causing premature failure but soft enough to minimize wheel vibrations.

Polyurethane treaded wheels can shoulder industrial loads and offer higher pitch noise reduction. Common durometers range from 70A to 70D. A soft polyurethane wheel such as ET-85 rolls easily and quietly and is ideal for applications that require industrial-strength performance with a softer touch. This tread will help cushion your ride and absorb some impact during the process of moving your loads. And while softer treads reduce noise more effectively, the downside is that they’re more prone to wear and tougher to roll manually.

2. Spring-loaded casters – These casters are designed with cantilevered spring mechanisms that support loads and dampen the shock of the floor and wheel connecting. Spring configurations are vertical or horizontal, which impacts the size of the caster. Our engineers at Caster Concepts can design many combinations of caster spring capacity, which provide varying load capacity and degrees of noise reduction at predetermined weights. Our engineers can also determine and design pre-load into the final product. Spring-loaded casters carry loads from a few hundred pounds to more than 20,000 pounds.

83 Series Spring Loaded Casters

CasterShox noise and vibration dampening

3. CasterShoX® – Our patented, shock-absorbing technology is new to the industry. The wheel houses a specially designed flexural spring in its hub and encases the spring with an elastomer. This muffles roughly 70 percent of cart noise without significant changes to caster design or caster housing. CasterShoX® has the distinction of being the most cost-effective noise reduction method that doesn’t require major design changes or budget overruns. Our engineers can also fit the wheels into existing caster rigs.

4. Dampening the axle – This includes mechanisms that suspend the axles within a formed polymer. It’s not used often because poor performance and premature failure can result.

5. Combining design solutions – In difficult applications our engineers can combine two or more of these suggestions to maximize noise reduction. For instance, many designs use the best wheel material for the application, and pair it with the spring-loaded caster or the shock absorbing wheel.

These five suggestions give customers a great starting point when incorporating noise reduction in a cart design. Our engineers at Caster Concepts engineering arm, Conceptual Innovations, have the expertise and experience to meet and solve your most difficult noise problems.