In industries like aerospace and automotive, efficiency and precision are crucial. Whether it’s handling sensitive aerospace components or transporting heavy automotive parts safely, aircraft ground support equipment and material handling systems must be reliable, durable, and safe. CasterShoX® shock-absorbing casters offer an innovative solution to address common challenges these industries face, including excessive workplace noise, damage to fragile loads, and safety risks for workers.

Up to 90% Noise Reduction* — Reducing Noise by up to 15 Decibels.**

Aerospace and automotive facilities are often high-noise environments due to machinery, moving carts, and heavy-duty equipment. This can create a disruptive work environment, lowering productivity and even posing a risk to workers’ hearing. CasterShoX® can significantly reduce noise pollution, achieving up to 90% noise reduction and decreasing noise by up to 15 decibels when compared to conventional casters.

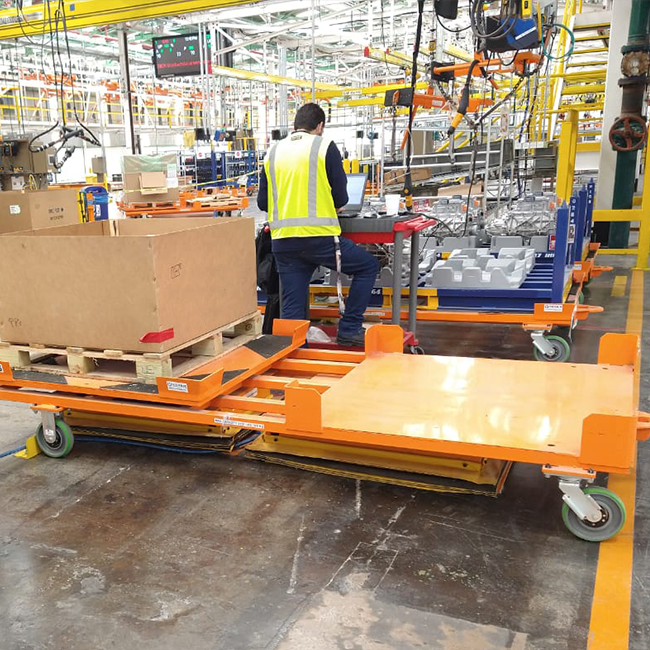

![]() Here’s a great example: A large auto manufacturer uses dollies to transport parts in one of its assembly plants. Pulled by a tugger in a five-dolly train, these carts created noise levels of 95db, 10db greater than OSHA’s recommended limit of 85db for continuous exposure over an 8-hour shift. With the noise at 95db, OSHA regulations limit operator exposure to 4 hours, which posed a significant challenge to the plant’s operational efficiency.

Here’s a great example: A large auto manufacturer uses dollies to transport parts in one of its assembly plants. Pulled by a tugger in a five-dolly train, these carts created noise levels of 95db, 10db greater than OSHA’s recommended limit of 85db for continuous exposure over an 8-hour shift. With the noise at 95db, OSHA regulations limit operator exposure to 4 hours, which posed a significant challenge to the plant’s operational efficiency.

Combining CasterShoX with a redesigned tow hitch bar reduced noise levels to 67db(A), significantly below OSHA’s 85db threshold. This represented a 31% reduction in noise from the original level of 95db and was 23% better than a competitor’s previously tested product.![]()

Reducing noise in production facilities contributes to a calmer, more focused work environment. It also helps businesses meet safety regulations, such as OSHA’s noise standards and reduces the need for hearing protection gear.

Transporting expensive aerospace components or fragile automotive parts can be costly, especially when equipment is exposed to constant shock and vibration. Customers often face costly repairs, replacements, and production delays due to damage sustained during transport. CasterShoX® casters address this pain point by reducing shock loads by up to 80%, providing the cushioning needed to protect valuable cargo and sensitive parts from damage.

This level of shock absorption helps extend the life of sensitive parts, ensures smoother operations, and reduces financial losses due to damaged goods. For aerospace, automotive, GSE equipment, and other industries where precision and product integrity are paramount, CasterShox can be a welcome necessity.

Vibration and shock from moving carts affect equipment and pose a safety risk to workers. Prolonged exposure to these vibrations can lead to injuries and fatigue, reducing overall workplace safety and efficiency. CasterShoX casters are engineered with superior vibration-dampening properties that protect workers by minimizing the impact of these forces, contributing to a safer working environment while helping companies stay compliant with safety regulations.

Choosing the right casters isn’t just about improving mobility—it’s about making long-term investments that enhance the efficiency, safety, and durability of your equipment and your operations. CasterShoX® casters are designed to offer superior performance, with noise reduction, shock absorption, and vibration dampening that protect both your equipment and your workforce.

Additional Advantages of CasterShox® Casters:

Spring-loaded casters certainly are better at mitigating shock and vibration compared to springless casters. However, spring-loaded casters have limitations. Metal springs absorb some shock, but because these springs are external to the wheel’s core, some vibration is still transferred to the equipment.

CasterShoX stands out because its elastomer springs are built directly into the wheel’s core. This design allows CasterShoX to absorb significantly more shock and vibration, protecting the equipment and ensuring smoother operation, even in the toughest conditions.

Take the first step towards reducing noise and protecting high-value equipment by exploring the benefits of CasterShoX®. Contact Caster Concepts today to learn more about this innovative solution can protect your workers and equipment on many levels.