Giving our customers the knowledge to make better-informed decisions.

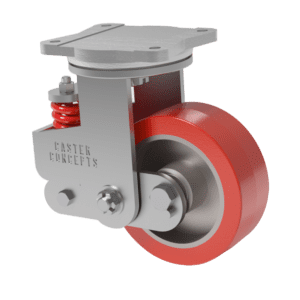

At Caster Concepts, we’re not just about selling products – we’re about solving your problems. And the more informed you are about your material handling challenges, the faster we can solve them quickly and efficiently.

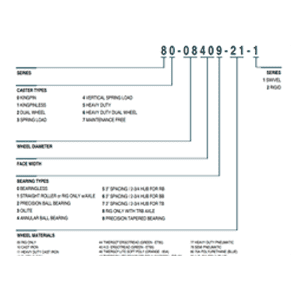

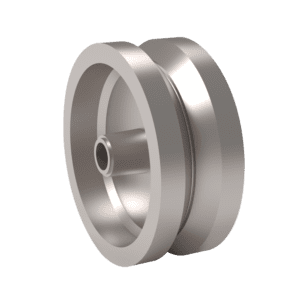

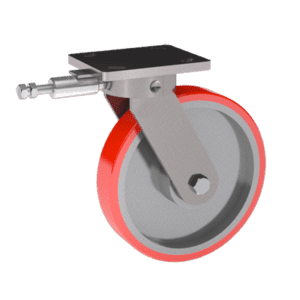

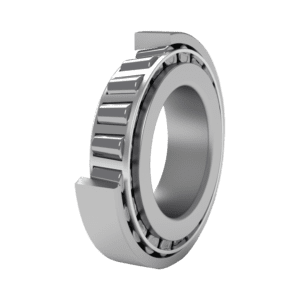

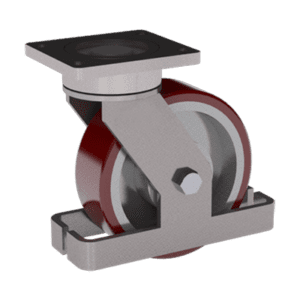

Our Caster Learning Center is here to help you make well-informed decisions about the type of caster you need. From reviewing our catalog to discovering our different caster configurations and polyurethane wheels to learning more about what makes up a caster, our goal is to give you the best information to help engineer the best solution to get you exactly what you need. All delivered on time, every time.