Description

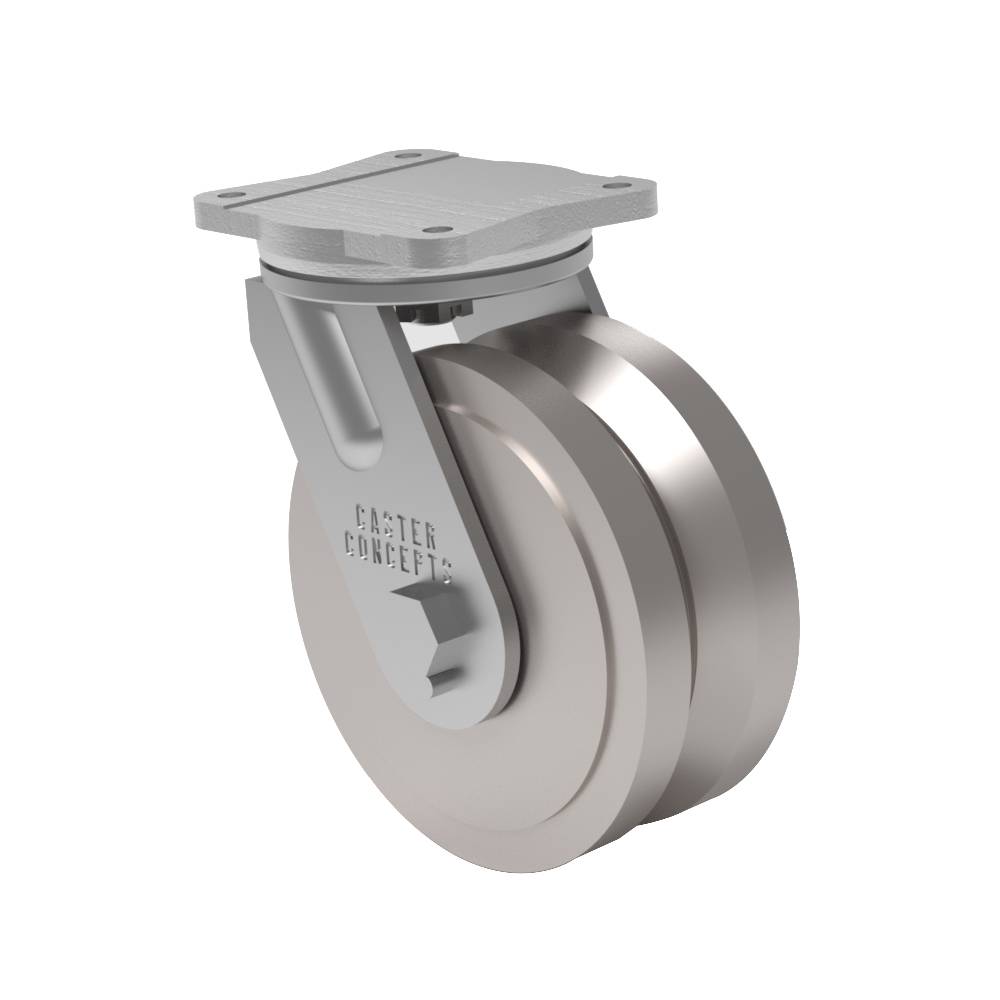

This 8-inch by 4-inch 85 series caster sets the standard for durability and precision with its high-quality construction. The yoke and top plate are forged through a drop forged process using C-1045 steel, ensuring exceptional strength and reliability. The kingpin is an integral component of the top plate, providing seamless integration. The top plate is machined to incorporate the raceway, while the threaded kingpin and yoke base raceway are machined to a 5-inch diameter. Although the raceway is not heat treated, a precision tapered load bearing (with dimensions of 3.875 inch ID x 5.00 inch OD) is positioned between the top plate and yoke base, enhancing precision and load-bearing capacity. To complete the assembly, a 1.25-inch precision tapered thrust bearing is pressed over the kingpin, engaging the yoke. This meticulous design results in a swivel section with outstanding load carrying capacity for its class. The 85 Series excels in providing an exceptionally tight tolerance fit, ensuring smooth and precise movements. Moreover, the integrally forged kingpin and slotted adjusting nut significantly contribute to the strength and longevity of the swivel section, further enhancing the caster’s lifespan.

Combined with Forged Steel wheels, these casters become a powerhouse solution for heavy-duty industrial applications. These wheels are hot forged from high carbon steel billets, enhancing their grain structure, ductility, and tensile strength (64,000 psi). With precision machining, they meet tight tolerances, ensuring flat surfaces with rounded edges. Offering the greatest load capacity, impact strength, and rollability among caster wheels. With the proper wheels and bearings, these wheels are capable of withstanding temperatures up to 800 degrees. Featuring our precision tapered bearings, the wheels are capable of absorbing excessive side thrust loading and can be used where high speed operation is essential, all with a load rating of 10000 lbs.