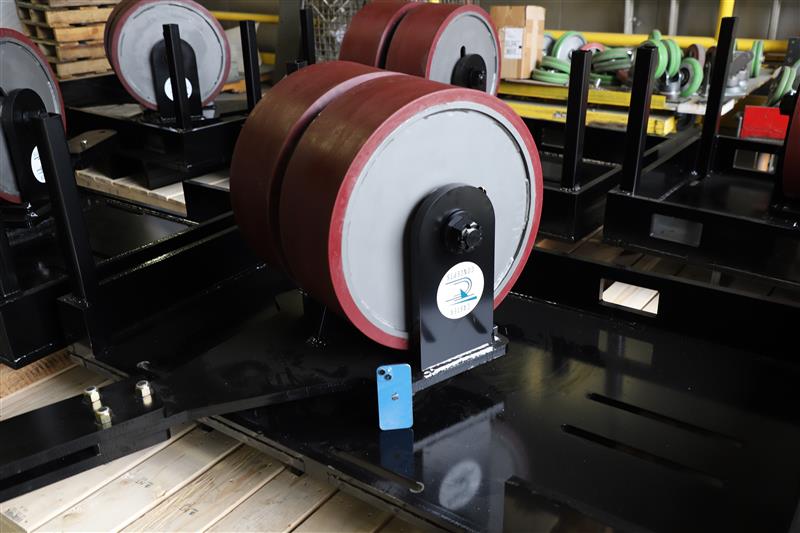

Heavy-duty, low-profile skates are designed to move modular buildings, containers, and oversized equipment safely and efficiently.

At Caster Concepts, we exist to solve the toughest challenges in mobility and manufacturing, empowering people, companies, and communities to achieve more. This commitment shows in every skate we build, from the materials we choose to the way we customize solutions others shy away from.

Modular transport skates from Caster Concepts are built to handle the real-world demands of modular construction, utility enclosures, and containerized systems. Whether you’re staging a unit inside a facility or positioning it on uneven jobsite ground, our skates deliver strength, control, and customization.

| 200,000 lb+ Capacity | Engineered with a 4:1 safety factor and customizable load handling |

| Modular Design | Optional dovetail, bolt-on, or fork pocket configurations for flexible integration |

| Customizable Options | From wheel material to integration type, tailor your skate to your application |

| Height | ≤ 14 inches (low profile) |

| Frame Material | High-strength steel, powder-coated |

Our dovetail-style interface is purpose-built for modular and container-based systems that demand rapid setup, secure engagement, and seamless detachment. Designed as a male-female wedge system, the dovetail allows each skate to slide directly into a receiver plate mounted on the module’s frame. Once inserted, a locking mechanism, such as a spring pin, bolt-through, or twist-lock, secures the caster in place with confidence.

This tool-free interface eliminates the downtime and strain associated with bolted or welded caster systems. Skates can be repositioned or reused between units without slowing down your operation. The result is a faster, safer, and more flexible approach to mobility, ideal for high-mix production environments, shared caster fleets, and job sites with ever-changing layouts.

By simplifying attachment and removal, the dovetail interface not only makes movement safer, it also reduces production and alignment time. That translates directly into faster cycle times, lower labor strain, and more throughput across your entire facility.

Download Spec Sheet