In industries such as electronics, manufacturing, and healthcare, even the slightest static discharge can damage sensitive components or compromise delicate processes. Casters can offset static by preventing the accumulation of static or dissipating electrostatic charges.

These casters are designed to withstand the rigors of demanding industrial environments, ensuring long-lasting performance and minimizing the need for frequent replacements, ultimately reducing maintenance costs and downtime.

Caster Concepts does not feature static-sensitive casters in our catalog, but we can design and manufacture a clean room or electrostatic dissipative (ESD) caster to your specific requirements.

Anti-Static and ESD Casters

Anti-static and ESD casters are the ultimate solution for environments where static electricity buildup poses a significant risk. These specialized caster wheels effectively prevent static buildup and dissipate electrical charges, safeguarding sensitive equipment and processes from potential damage.

Clean Room Casters

Maintaining an ultra-clean atmosphere is paramount in cleanrooms. Cleanroom casters are designed to prevent the generation and accumulation of static electricity, which can attract and trap unwanted particles. By incorporating advanced static-dissipative wheel materials and unique tread patterns, these casters effectively mitigate the risk of electrostatic discharge (ESD) and facilitate smooth, controlled movement without compromising the integrity of the cleanroom.

ESD and anti-static casters eliminate the risk of static discharge, creating a safer working environment for personnel and sensitive operations in a variety of applications. By minimizing particle generation and static buildup, cleanroom casters help maintain the ultra-clean environment necessary for sensitive processes and products.

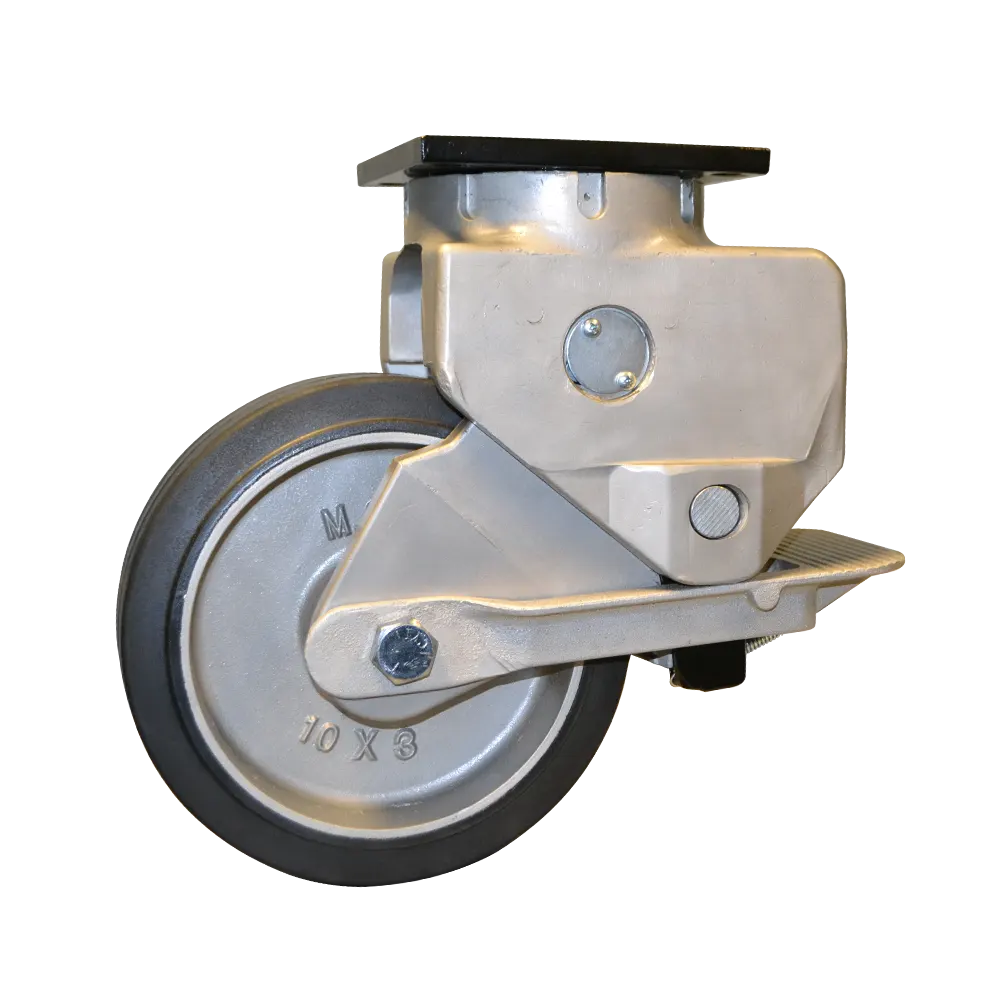

Caster Concepts has a wide variety of caster options. Many of these not only improve function – but also provide safety and add longevity to the product. When considering safety options, the most common consideration would be caster locks, caster brakes, toe guards, and reinforced legs. Options that extend the life of a caster are primarily options that seal the bearing of the caster to prevent contamination of the precision parts.

Other options include threaded zerks for when an application is difficult and high level of maintenance is required and track brush wipers that keep debris from stopping movement or damaging a wheel. These options can be added at the time of manufacturing or after the caster is fully assembled.