An aerospace manufacturer had trouble with a heavy-duty swivel casters wheels that supported a sizeable finishing mandrel. It was used in sanding section 41 (Cockpit, Galley, and Crew Quarters) of the Boeing 787 “Dreamliner” aircraft. The fragile and heavy caster load averaged 35,000 lbs. per caster. In addition, floor variations in surface height and space limitations prevented caster shift while swiveling. These challenges caused binding issues and slowed production.

The tool design engineering house found Caster Concepts and implored them to develop a heavy duty swivel casters wheels that would eliminate the ‘castering effect’ as the casters went to swivel.

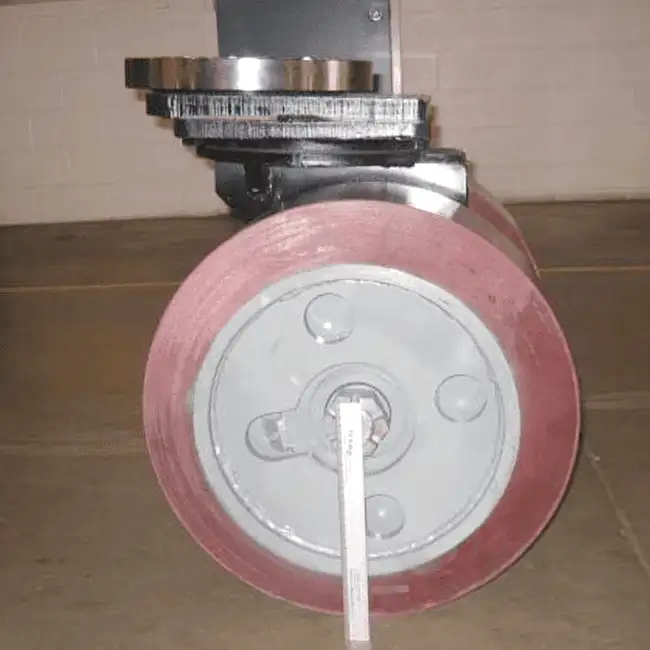

Caster Concepts joined forces with Boeing Offload Tool Design Engineering in a dynamic collaboration. Together, they crafted a cutting edge double swivel caster tailored for the finishing mandrel. This heavy duty swivel caster redefines durability and precision by boasting a primary swivel with a super high capacity precision slew bearing and a secondary bearing featuring a robust 35,000 lbs. capacity 99 series swivel section.