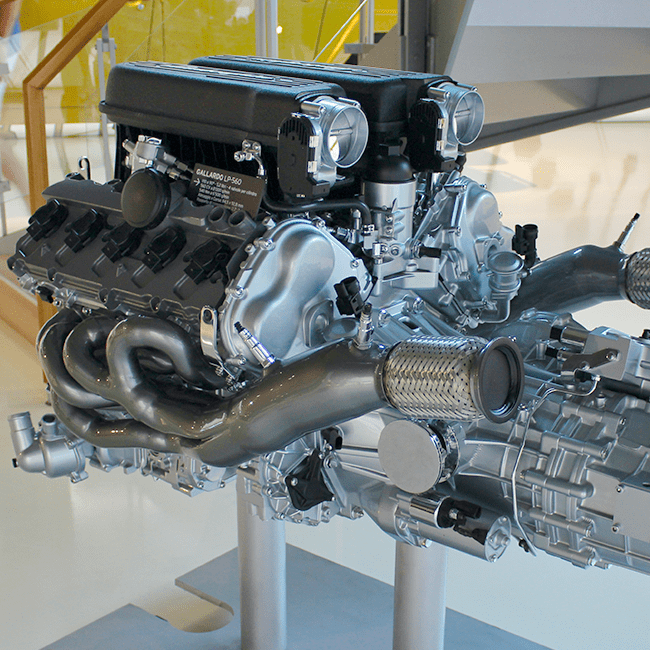

A major automotive manufacturer has a plant down south that is a busy place, cranking out almost 700,000 engines in 2017 alone. If this level of engine production wasn’t a heavy enough undertaking, a bigger challenge was moving them.

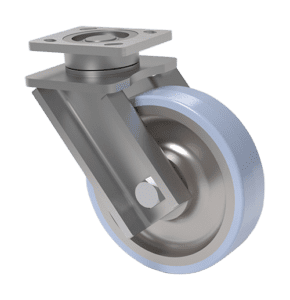

Fork trucks and tuggers were used to pull the 4,000 to 5,000 lb. carts containing these engines. Constant towing 24/7 was a continuous strain on the rigs and wheels, causing them to bend and break. Even with the reinforced casters they were using, they couldn’t hold up to the abuse.

It was taking a heavy toll on the casters and replacing them was becoming a monthly to bi-monthly process. It cost the manufacturer time, it was eating money, and it was turning into a significant safety concern. Something needed to be done…quickly.

This highly beneficial setup was complemented by a TR poly wheel that proved to be an exceptional choice due to its high tear resistance and its resistance to scrap pickup. The casters are still in use, and not one has failed for more than a year. This setup also allowed the plant to pull team leads off caster replacement and spend time in other areas. Caster Concepts is still receiving orders to replace the original standard 8×2 casters as soon as they bend and break.

This highly beneficial setup was complemented by a TR poly wheel that proved to be an exceptional choice due to its high tear resistance and its resistance to scrap pickup. The casters are still in use, and not one has failed for more than a year. This setup also allowed the plant to pull team leads off caster replacement and spend time in other areas. Caster Concepts is still receiving orders to replace the original standard 8×2 casters as soon as they bend and break.