The power generation industry faces enormous challenges — literally. Every day, manufacturers must move diesel engines, generator assemblies, oversized control centers, and other critical infrastructure weighing anywhere from 20,000 lbs to over 250,000 lbs. These components power data centers, industrial facilities, hospitals, and the grid itself.

When these structures can’t move efficiently, safely, or cost-effectively, the entire operation grinds to a halt.

Caster Concepts engineers mobility systems that handle the loads, environments, and obstacles that standard equipment simply cannot. Because in power generation, failure is not an option.

1. Heavier Weight Destroys Standard Equipment

1. Heavier Weight Destroys Standard EquipmentGenerators, diesel engines, and power modules push equipment far beyond normal capacity. Generator platforms can range between 80,000 and 150,000 pounds, and control centers can go north of 250,000 lbs.

Off-the-shelf casters and machine skates break under these conditions — often causing downtime, delays, and dangerous failures.

Many movement challenges happen where cranes cannot operate, such as inside generator enclosures or spaces limited by low ceilings or narrow, confined pathways.

Even when cranes are available, there are still the challenges of high rental and operating costs, safety considerations for moving large, heavy equipment overhead, and limited maneuverability. Most manufacturers want a safer, more cost-effective alternative.

In staging yards and outdoor facilities, teams often deal with:

Dirt or Gravel

Uneven concrete

Weather-worn surfaces

Power-gen operations require casters that maintain traction, distribute weight evenly, and navigate unpredictable terrain. Pneumatic wheels are especially a good choice for outdoor use. The pneumatic tires cushion the load and roll over obstructions and uneven surfaces with ease.

Moving a 20-Ton Diesel Engine into a Space No Crane Can ReachThe Problem: A 40,000-lb diesel engine on a steel I-beam sled needed to be moved into a generator enclosure:

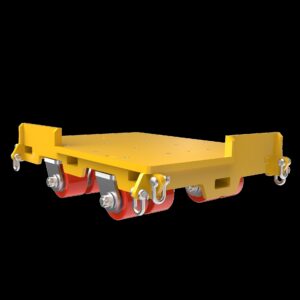

The Solution: Four equipment skates fitted with Dual 99 Series Casters

This solution delivered unrestricted movement inside a restricted environment.

|

AI data centers depend on uninterrupted power. One of our customers builds primary and backup power control centers — 53 ft long, 18 ft wide, and weighing 250,000 lbs. These are the command hubs that keep AI server farms running.

Standard mover skates failed repeatedly

Over $400,000 in replacement costs annually

Production delays from constant equipment breakdowns

No manufacturer was willing to build a custom solution… until Caster Concepts

Skate wheels were failing under extreme load with wheel bearings suffering early breakdowns.

The structures needed to pivot on uneven ground for loading, and traditional casters weren’t distributing the weight properly or safely.

Working with the customer, Caster Concepts’ engineering developed a new mobility system, designed in collaboration with the customer, to solve the previously impossible challenge of constant caster failure. The new system features:

Working with the customer, Caster Concepts’ engineering developed a new mobility system, designed in collaboration with the customer, to solve the previously impossible challenge of constant caster failure. The new system features:

A heavy-duty spring-loaded rigid center caster for pivot control

A custom skate designed for extreme load distribution

Two quad-wheel 91 Series rigid casters

Each wheel: 6″ x 3″, load rated for 40,000 lbs

This wasn’t a solution pulled from a catalog or off a shelf — it was engineered to solve an impossible problem.

• Zero caster or skate failures •Production delays eliminated • $400,000/year saved in replacement costs • Reliable, controlled movement of 250,000-lb structures

When other manufacturers said it can’t be done, we engineered the solution. And in the process, created another long-term engineering partnership.

TALK TO A SOLUTIONS SPECIALIST

Engineered for Extreme-Duty Movement — We don’t follow standard load charts — we rewrite them.

American-Made Quality — Every caster is manufactured under our roof for total control over performance.

Custom Solutions for Complex Challenges — We solve problems others walk away from.

Built for Safety — Every mobility system is engineered to protect workers and equipment.

Performance on Any Surface — From smooth assembly floors to rugged outdoor yards, our casters endure where others fail.

Whether you’re transporting diesel engines, relocating massive generator modules, or moving 250,000-lb power control centers for AI infrastructure, Caster Concepts delivers the durability, stability, and engineering excellence required to keep power-generation operations in motion.

If you’re facing a mobility challenge that others won’t touch — that’s exactly where we excel. Contact us for an engineered solution for your specific needs.