The old adage, “never judge a book by its cover,” applies, of course, to more than just books. In the Automotive and Aerospace manufacturing world, this is especially true – it is often the contribution of components that reside out of the spotlight that have the greatest impact on productivity, efficiency and ROI.

The same can be said for heavy-duty casters – particularly ones where engineering and technology have made some below-the-surface improvements that have a big impact on outward performance.

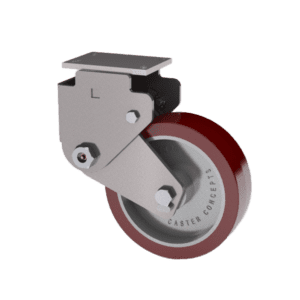

With CastershoX®, this feat of engineering has packed significant advances in noise reduction and shock absorption into an industrial caster that looks like – and fits into the same footprint as — a traditional caster.

|

Traditionally, the role of noise reduction in industrial casters was left to a spring-loading mechanism that is actually designed to reduce shock — noise reduction is a by-product on these casters. While effective to an extent, such spring-loaded industrial casters use a coiled metal spring to dissipate shock, which in turn causes the springs to expand and retract (bounce) repetitively until the shock impact is dissipated. The spring is usually placed above the axle of the wheel on the caster and, therefore, transfers vibration to the cart and its contents, resulting in noise and possibly damage to the cart’s contents.

By removing the wheel from the yoke, the patented SHOX® absorption unit is revealed. This innovative component gives CastershoX® the ability to achieve up to 90 percent noise reduction*, a feat no other industrial caster can achieve. The SHOX® absorption unit integrates a patented technology to reduce the effects of shock loading and potentially eliminationg noise and vibration, protecting both workers and the components they are moving.

|

|

|

CastershoX® users benefit from its proprietary technology and design comprising its components and its placement at the core of the industrial caster. The combination ensures that the CastershoX assembly contains the impact and dampens it – delivering a performance that is like that of a shock absorber in a vehicle. These shock-absorbing properties reduce shock loads by up to 80%, protecting both loads and transportation equipment. In addition, vibration dampening protects workers from injury by reducing the vibration when manually moving carts.

By containing the shock, CastershoX also reduces noise tremendously — in some cases by as much as 15 decibels db(A). Because the impact of noise grows exponentially as it gets louder, a decrease of 15 decibels could equal as much as a 90 percent reduction in noise.

CasterShox delivers unparalleled noise reduction and shock absorption, making it the ideal choice for industries such as Automotive and Aerospace where OSHA-mandated noise levels and material handling safety are paramount. To learn more about the many benefits of CastershoX, please contact one of our Solution Specialists.