Do a Google search, and you can find all the different numbers relating to overexertion injuries. Companies spend a lot of money every year dealing with the costs of these types of injuries. In 2023 alone, it’s estimated that this type of occupational injury costs businesses $12.84 billion. And from what the facts show, it is only going to get worse. Which makes finding a good ergonomic solution more important than ever.

Yet many of these costly injuries can be avoided by simply choosing the right caster, as demonstrated in our webinar: Ergo Solutions, Casters as a Material Handling Solution.

In this webinar (which you can watch below, or download this PDF) Ergonauts Performance Technologies, along with Solutions Expert Doug Backinger of Caster Concepts, provide compelling reasons why choosing the right caster solution can significantly improve safety and save companies a lot of money by reducing stress injuries.

Takeaway 1. The Liberty Mutual Workplace Safety Index developed a safety standard for push forces. They determined that a push force of 40 lbs. or less is required for 90% of the population to safely move a material handling cart.

{At 6:08 — Economics of Proper Ergonomics}

With material handling carts getting heavier and harder for employees to push, safety standards were developed to determine what percentages of the population could safely move a cart based on the amount of push force needed to start and move the cart. In most applications, carts are being moved multiple times a day, and such repetitive tasks add to the fatigue factor.

With material handling carts getting heavier and harder for employees to push, safety standards were developed to determine what percentages of the population could safely move a cart based on the amount of push force needed to start and move the cart. In most applications, carts are being moved multiple times a day, and such repetitive tasks add to the fatigue factor.

For example, if you have a cart that takes 70 pounds to push, that’s only going to be safe for about 38% of the population. So, for every 100 employees you have, 62 are at potential risk of injury. Reduce that to 50 lbs. push force, and you have a big jump in the percentage that is safe to push. At that weight, now you’re up to 82% and the main standard we see in Industry.

Takeaway 2. An 80% reduction in push force was achieved at a plant by changing the casters to a split-wheel design and changing to a tread compound to a high rebound formulation. The result, the tread cart push force was reduced from +200 lbs. to 40 lbs. for a major Tire Manufacturer.

{At 26:55 — Reducing Push Force on Tread Cart}

The more contact your caster has with the ground, the more friction you will have. You want to get that contact as small as possible to get the wheel rolling while considering the stress that will be put on that reduced area.

In the last 10-15 years, we’ve seen more split-tread wheels, which allow you to take advantage of wider wheels and then reduce the amount of scrubbing. You can stack these individual rotating discs together so as the caster swivels around each of the wheels, they can rotate at a different rate and really reduce the amount of scrubbing.

The other factor is the wheel tread. The harder the wheel, the easier it is to roll. However, a harder wheel is harder on floors, so you have tradeoffs. Polyurethane wheels in the 85- 95A hardness range are often the go-to choice.

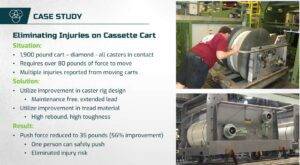

Takeaway 3. Moving a Cassette Cart required over 80 lbs. of push force, which resulted in multiple injuries. Caster Concepts built casters with extended leads, maintenance-free bearings, and high rebound polyurethane, which reduced the push force to 35 lbs. and eliminated injuries.

{ At 28:32 — Eliminating Injuries on Cassette Cart}

The longer that swivel lead is, or the farther that wheel is away from the center of the pivot, the easier that Caster is going to swivel. There is an optimal point of extension based on weight because as you extend out more, you’re putting more stress on the swivel section, which can make it harder to swivel. Caster Concepts’ engineers design casters to our customers’ exact specifications.

The longer that swivel lead is, or the farther that wheel is away from the center of the pivot, the easier that Caster is going to swivel. There is an optimal point of extension based on weight because as you extend out more, you’re putting more stress on the swivel section, which can make it harder to swivel. Caster Concepts’ engineers design casters to our customers’ exact specifications.

Doug also answers more questions from our panel {at 32:20 in the presentation}, which is where the Q&A session starts. Be sure to download the webinar and presentation to learn more about how choosing the right caster can reduce costly overexertion injuries and boost productivity in your facility.

If you’d like to contact Doug about ways to improve operations and safety in your facility, email him at dbackinger@casterconcepts.com or call 517-680-7966.