This failure usually results from not taking into consideration total weight loads and uneven load distribution.

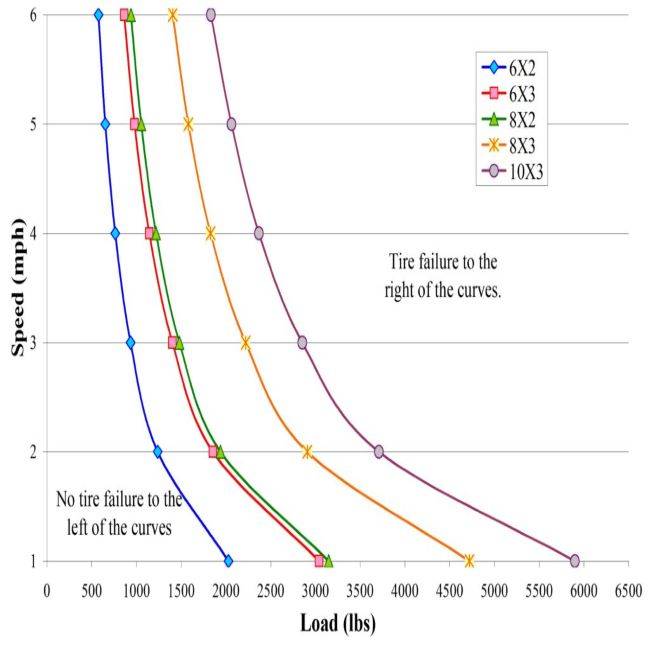

The first thing to evaluate is how the caster application is being used and moved. Any application traveling faster than walking speeds can cause the wheel’s polyurethane to fail prematurely (The three main types of polyurethane failure covered here). Towing much faster than 5 MPH can also result in premature bearing failure due to excessive speeds.

The first thing to evaluate is how the caster application is being used and moved. Any application traveling faster than walking speeds can cause the wheel’s polyurethane to fail prematurely (The three main types of polyurethane failure covered here). Towing much faster than 5 MPH can also result in premature bearing failure due to excessive speeds.

This also applies to continuous-use applications or if the caster is used for three shifts in succession. Poly tires can build up heat from high speeds, high loads, or a combination of both. As the temperature rises, the bond degrades, which can ultimately lead to failure. It’s important to know what we call in the industry “load, speed, and duty cycle”.

You also need to be aware of how your payload is placed on your application. Shock and side loading are hard on casters, although tapered bearings help in relation to side loading. A sudden application of weight can also cause the carts to bounce or tip. This can result in the weight not being distributed evenly over all the casters. Or, if your payload is situated closer to the front than the back (or vice versa), make sure that particular area is specified to handle the concentrated weight.

Next, you want to assess what the environment can do to the metal, grease, polyurethane, and anything else that goes into your standard Caster. Saltwater can destroy simple iron ores and steels due to the acidity in combination with the oxidization of iron/steel and water. We offer solutions to combat this, which include aluminum and stainless steel, as well as powder coating, and plating. Cleaning products can also shorten your caster’s lifespan, so it is important to disclose all cleaning information if that pertains to your application.

If you are working in an area that produces or is consistently surrounded by debris, it is important to specify that you need the caster and wheel bearings to be sealed. Failure to seal bearings in sandblasting, boat manufacturing, machining, or any other debris-filled application will cause the bearings to seize — limiting mobility tremendously.

If you are working in an area that produces or is consistently surrounded by debris, it is important to specify that you need the caster and wheel bearings to be sealed. Failure to seal bearings in sandblasting, boat manufacturing, machining, or any other debris-filled application will cause the bearings to seize — limiting mobility tremendously.

Although we’ve talked about this, knowing the weight of both your cart and your payload is CRITICAL in making sure a caster does not fail prematurely. There is a reason why we ask all these questions. I’ve had a few instances working here where a customer gets a product from another company, tests it out, and comes back with a premature failure because they didn’t account for the cart weight in the application — causing a failure of internal safety standard tests.

I’ve also had moments where the customer is convinced that they need new casters, only to find out that their load was not as much as they had guessed, and they were already passing safety standards. It’s important to know your weight to see if you need an ergonomic solution, or if you need more spec’d on your weight than initially thought.

That’s why it is so important to everyone that correct and accurate information is conveyed both ways. That is how We Build Trust! For more educational information check out our Learning Center here.