Purchasing the wrong caster can lead to many different problems. These include (but aren’t limited to) potential equipment damage, injury to personnel, delays to projects or tasks, and excessive capital expenses. To avoid these potential issues, it’s always a good idea to double, sometimes triple-check the specifications of the caster you need before making a purchase and to contact the seller or manufacturer if you have any questions or concerns.

When selecting casters, keep in mind these considerations to ensure that you choose the right caster for the job:

Load Capacity: Consider the weight of the object being moved and ensure that the caster you choose can support that weight. The load capacity of a caster is the maximum weight it can carry. Besides the main load, consider any additional weight that may be added, such as equipment or supplies. Also, additional safety factors may be required that will add to the total weight capacity of the casters.

Application: Consider the environment and conditions the caster will be used in. For instance, if the caster will be used in a damp or wet environment, it’s important to choose a caster with a special coating or one made of a corrosion-resistant material such as Aluminum to prevent rust or deterioration. On the other hand, if the caster will be used in a clean room or laboratory, a caster with a sealed raceway and no exposed ball bearings may be necessary to prevent contamination. Another common thing for clean room applications is ESD wheels.

Application: Consider the environment and conditions the caster will be used in. For instance, if the caster will be used in a damp or wet environment, it’s important to choose a caster with a special coating or one made of a corrosion-resistant material such as Aluminum to prevent rust or deterioration. On the other hand, if the caster will be used in a clean room or laboratory, a caster with a sealed raceway and no exposed ball bearings may be necessary to prevent contamination. Another common thing for clean room applications is ESD wheels.

Floor Type: Consider the type of flooring the caster will be used on. Ensure that the wheel material is selected accordingly. Different wheel materials are suitable for different types of flooring. For instance, hard wheels made of materials such as steel or nylon are typically better suited for concrete or tile floors, while soft wheels made of materials such as rubber or polyurethane are better suited for applications across tile or epoxy-coated concrete. It’s important to note that other than frost, hard wheels are a concrete floor’s worst enemy. Want to keep your floors intact? Go with Poly or Rubber.

RELATED: Selecting the right caster.

Caster Size: Consider the size of the caster in relation to the object it will be attached to, and ensure that it provides adequate stability. The size of the caster typically refers to the diameter of the wheel, and it can range from a few inches to several inches. A caster that is too small may not provide enough stability, while a caster that is too large may not fit in the available space or may make the cart ride too high in applications where clearance is a factor.

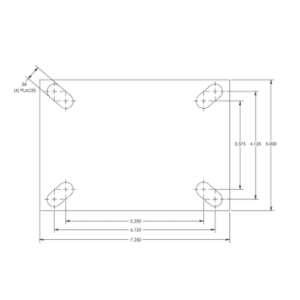

Mounting Type: The mounting type of a caster refers to the way it is attached to the object it will be supporting. The two most common types of mounting are stem mounting and plate mounting. Stem mounting involves inserting a stem into a pre-drilled hole in the object, while plate mounting involves attaching the caster to a flat surface using screws or bolts. (Note that Caster Concepts does not offer a standard stem caster; we only carry standard offerings in plate casters. Mounting type can also be a determinate of capacity, as rule of thumb is stem casters are for light duty and anything above is a variation of plate casters.

Mounting Type: The mounting type of a caster refers to the way it is attached to the object it will be supporting. The two most common types of mounting are stem mounting and plate mounting. Stem mounting involves inserting a stem into a pre-drilled hole in the object, while plate mounting involves attaching the caster to a flat surface using screws or bolts. (Note that Caster Concepts does not offer a standard stem caster; we only carry standard offerings in plate casters. Mounting type can also be a determinate of capacity, as rule of thumb is stem casters are for light duty and anything above is a variation of plate casters.

Special Features: Consider any special features you may need, such as locking brakes or a swivel lock, or if you are looking for a specialty caster like the Swivel on Swivel or Suspension. Locking brakes are useful for preventing a caster from rolling, which can be particularly important for safety or stability. A swivel lock is useful for fixing the orientation of a caster in a particular direction, which can be particularly important for maneuvering around tight spaces or obstacles. Swivel on Swivel casters are great for tight and hard-to-reach areas due to their next-level maneuverability. Suspension Casters can stabilize the load, so it’s important to know load sensitivity.

Purchasing the wrong caster can lead to several problems, but by carefully considering your caster needs and specifications before making a purchase, you can ensure that you choose the right caster for the job. Keep in mind, that there are numerous things that can affect the life of your casters. It’s critical to the success of your applications to let the representative or manufacturer know what conditions the caster will be dealing with.