For polyurethane thin-treaded wheels, the prominent mode of failure is that of the bond between the tread and hub. While numerous factors can create such a failure mode, the predominant mechanism leading to bond failure is excessive heat in the bond region. Polyurethane tires can build up heat from high speeds, high loads, or a combination of both, typically generated by the tread itself. Subject to continuous deformation, the urethane tread transforms this mechanical deformation through the hysteresis of the material into thermal energy. As the temperature rises, the bond degrades, ultimately leading to failure.

Caster Concepts (CCI) has developed a predictive failure model in polyurethane-treaded wheels based on the operating conditions of the wheel (i.e., load speed, ambient temperature). This formula provides a better understanding of polyurethane tires and how they will react in different applications, allowing CCI engineers to spec out the right wheel for any customer’s application.

Polyurethane tires generate heat from the hysteresis of the urethane when it is cyclically deformed under load. This energy generation is related to the load and speed of the wheel as well as the physical characteristics – diameter, width, and tire thickness. Obeying the law of energy conservation, the energy generated is absorbed by the wheel core or expelled through convective heat loss. When the energy absorbed and the energy lost to convection are summed together, they equal the energy generated by the cyclic deformation. This equation results in a first-order differential equation that can predict the final temperature the wheel will reach.

Solving the wheel failure prediction equation required solving two unknown parameters during testing. The first was the convective heat transfer coefficient, hA. The second is dependent on the urethane material used. We called this the material heat generation coefficient, kHG, for short.

![]()

Key:

v is the velocity of the wheel in miles per hour

R is the radius of the wheel

L is the load on the wheel in pounds

s is the tire thickness in inches

w is the tire width in inches

TAMB is the ambient temperature of the surroundings in degrees F

T∞ is the steady state temperature of the wheel in degrees F

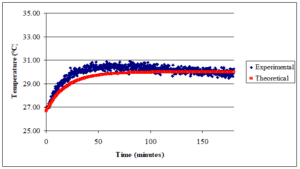

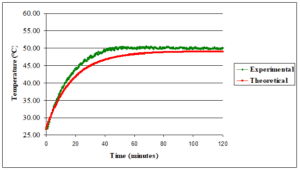

Testing was performed on various wheel sizes and polyurethanes to verify the equation. The results below show that the failure prediction equation accurately predicts the steady state temperature of the wheel within 5% for a given speed, load, and wheel size.

Figure 1: Actual vs. theoretical temperature profile of an 8×2 polyurethane treaded wheel running at 0.9 m/s and 2,225 N (2 mph and 500 lbs).

Figure 2: Actual vs. theoretical temperature profile of an 8×2 polyurethane treaded wheel running at 2.24 m/s and 3,560 N (5 mph and 800 lbs).

The prediction equation does begin to break down when the tire deflection under load exceeds 10%. Once 10% deflection is reached, the heat generation begins to change and grows exponentially, so the wheels are more likely to fail.

The variations in the failure prediction equation between theoretical and actual results can be attributed to many factors. Precision error in all computer sensors and equipment is listed at .05%. Force load cell resolution is approximately 111 N (25 pounds). The positioning of the IR sensor could also give a fluctuation in temperature readings of about ±2° C. There is also some contributable human error in reading the temperature profile graphs, approximated at ±1° C.

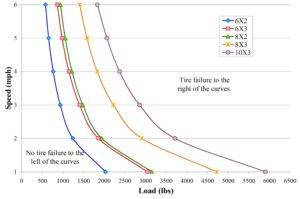

The final temperature of the wheel can be predicted from a given speed and load. This temperature can be compared to the failure temperature to determine if the polyurethane tire will withstand the applied load and speed. The equation will predict the final temperature within 5%. This equation can also be applied to wheels of different diameters and widths. Figure 3 gives the predicted load/speed combinations that will result in failure for the specified wheel size. If the load/speed combination falls to the right of the curve for a specific wheel size, then the tire is predicted to fail. If the combination falls to the left of the curve, the wheel/tire combination will perform successfully at those parameters.

Figure 3: Combinations of Load and Speed to Induce Failure in a Polyurethane Wheel

The equation is only valid for thin-tread polyurethane tires. When the tread becomes thick (greater than 0.02 m (¾ inches)), the heat becomes trapped in the urethane due to its insulating properties, and the wheel does not follow the lumped capacitive model.

The equation also begins to break down when tire deflection exceeds 10% of the thickness. This is due to the tire being overstressed, leading to heat generation and the breakdown of the material which increases the speed of the failure process.

The predictive failure model is useful for determining the correct wheel and urethane tire combination for specific applications without the need for testing. With the formula developed, only a few baseline tests are needed to develop the kHG for any urethane. Once a baseline kHG is developed, the formula can be used as a quality control tool to monitor tire/bond performance. Since kHG is affected by the bond strength, a poor bond will yield a higher kHG which can then be compared to the baseline. Variations in the urethane stoichiometry will also affect the kHG and the performance of a wheel.

Contact Caster Concepts Engineering department today to custom design a polyurethane treaded wheel for your demanding application.