A maintenance-free caster refers to a caster wheel or a complete caster assembly that requires minimal or no maintenance during its operational lifespan. In the world of heavy duty industrial casters, “maintenance-free” casters also come with a sealed precision ball bearing.

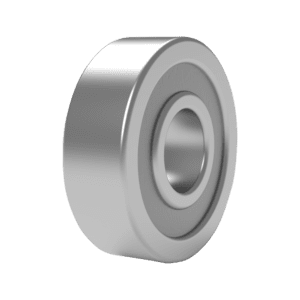

A sealed precision ball bearing is designed and manufactured to last the life of the bearing without any maintenance or greasing. These bearings are manufactured with a heat treated ball race along with steel balls. The key to being maintenance free is pumping these bearings with grease and then assembling seals on each side of the ball raceway. The importance of the seals is, not only to keep grease locked in, but prevent any dirt or liquid from getting in.

A sealed precision ball bearing is designed and manufactured to last the life of the bearing without any maintenance or greasing. These bearings are manufactured with a heat treated ball race along with steel balls. The key to being maintenance free is pumping these bearings with grease and then assembling seals on each side of the ball raceway. The importance of the seals is, not only to keep grease locked in, but prevent any dirt or liquid from getting in.

Benefits of maintenance-free casters

Here are some of the benefits associated with maintenance-free casters:

Typical caster designs, kingpin and kingpinless, are constructed with many similar features, including ball bearings. However, in maintenance free caster designs the construction of the bearings is enclosed within the product, not sealed. These swivel sections have machined and heat treated raceways along carbon balls built right into the top plate and yoke base. This creates a need to be greased and continue to be greased as they lack the sealed swivel section. Over time and demanding industrial use, dirt and liquids can get into the swivel section, pushing out or drying up lubricant, making it very difficult to rotate. These types of casters often require constant maintenance to keep the swivel section lubricated.

Although kingpin and kingpinless casters can last many years with the correct maintenance program and consistent lubrication schedule, most facilities do not have a good maintenance program for their industrial casters and wheels.

This is why maintenance free casters provide such a cost savings benefit. Besides the elimination of routine maintenance and regular greasing, the most important attribute of maintenance free casters is their ability to perform in the toughest industrial environments with extended caster life and minimal caster replacement.

Please feel free to contact me at kmyers@casterconcepts.com for any further industrial caster questions.