When moving heavy loads exceeding 5,000 lbs, choosing the right caster isn’t just about mobility. Safety, efficiency, and durability are also important. Stem casters and plate casters are the most common designs, each with unique advantages. Let’s compare them to find the best option for your material handling needs.

Stem casters feature a cylindrical or threaded stem that inserts directly into the mounting surface. This can be a hollow tube or a pre-installed socket.

Stem casters feature a cylindrical or threaded stem that inserts directly into the mounting surface. This can be a hollow tube or a pre-installed socket.

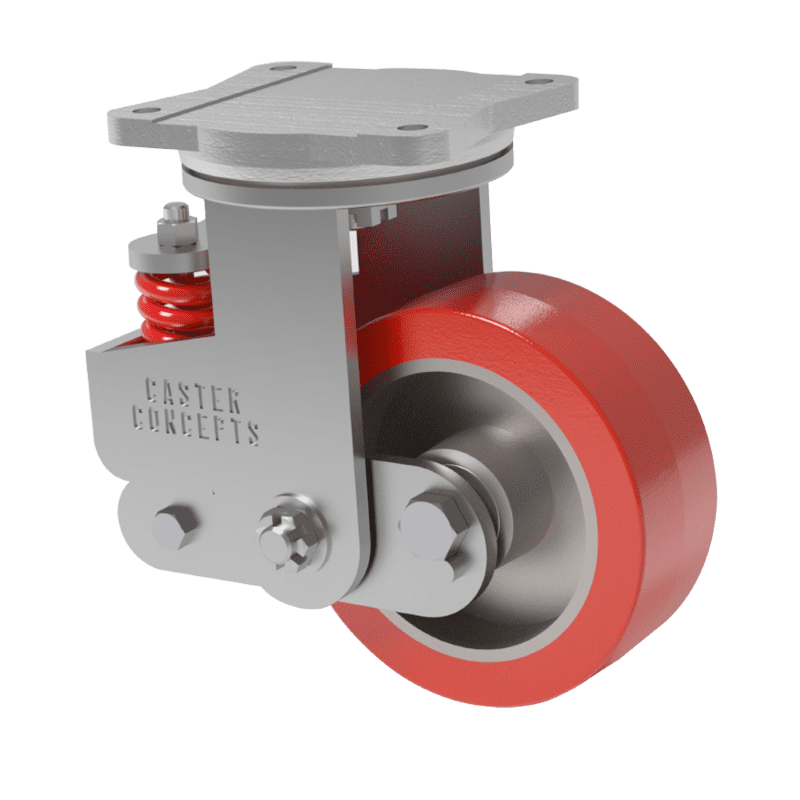

Top Plate Casters are the most common type of caster assembly, providing mobility for a wide variety of material handling applications. One big advantage is the caster mounting plate (top plate) offers more surface area than a stem caster. And that means better weight distribution, allowing a plate caster to handle heavier weight loads than a stem caster. Our plate casters come in a wide variety of options and weight capacities.

Top Plate Casters are the most common type of caster assembly, providing mobility for a wide variety of material handling applications. One big advantage is the caster mounting plate (top plate) offers more surface area than a stem caster. And that means better weight distribution, allowing a plate caster to handle heavier weight loads than a stem caster. Our plate casters come in a wide variety of options and weight capacities.

Caster Concepts only carries plate casters, which are available in kingpin and kingpinless designs, because of their ability to handle heavier loads.

Engine Dolly

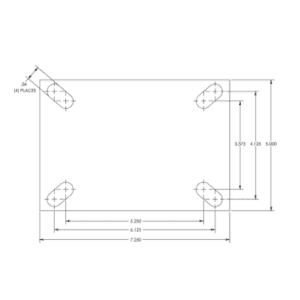

Pro Tip: When using plate casters, ensure you have the correct plate size. To determine this, you will want to measure the bolt-hole spacing:

Both stem and plate casters have their strengths. However, for loads exceeding 5,000 lbs, plate casters are often the go-to solution for stability, durability, and safety.

Contact us today if you’re unsure which caster type is right for your application. Our engineering experts are here to guide you toward the best solution for your heavy-duty material handling needs. Let’s move your business forward with confidence!