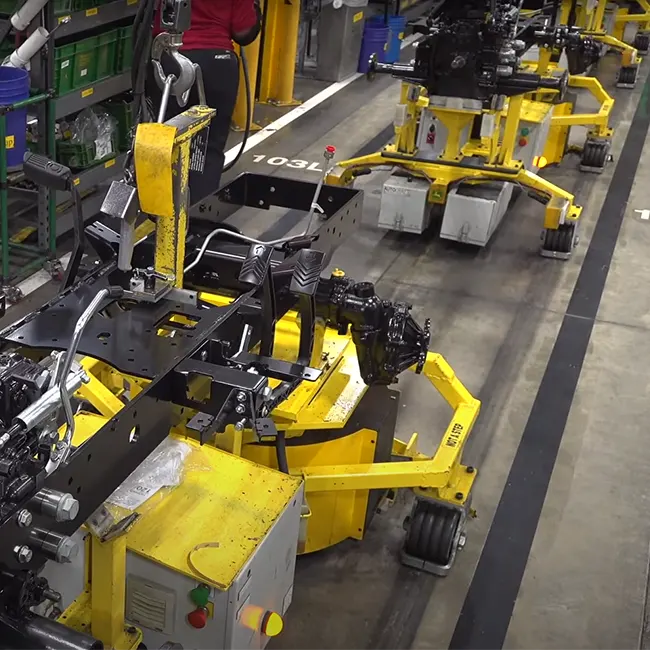

Automated Guided Vehicles (AGVs) have become essential in various industries, particularly manufacturing and warehousing environments. These vehicles are designed to transport materials efficiently and autonomously, improving productivity and reducing labor costs. One of the critical factors influencing AGV performance is the selection of appropriate casters, which can help these heavy duty AGVs maneuver easily and use less power.

The proper caster can significantly impact the ease of operation and power consumption, ultimately contributing to overall efficiency. For this reason, they play a critical role in achieving the desired output from an AGV system.

Key Takeaways

|

Several factors must be considered when choosing casters for your heavy duty AGV. These include load weight capacity, material type, and rolling resistance. Investing in high-quality, maintenance-free casters can save money on repairs and replacements while minimizing the safety risks associated with inadequate casters.

When selecting the best caster for your AGV, consider the following key elements:

First, you must ensure the caster can support the maximum weight anticipated on the AGV. This means you’ll have to choose a caster that can accommodate and exceed (for safety reasons) the heaviest load your AGV will transport to prevent caster failure from overloading.

Low-profile caster wheels keep the center of gravity lower, as well as the load’s overall clearance height. They can typically withstand higher amounts of weight associated with medium-duty industrial applications. In fact, many can support 1,000 pounds or more each.

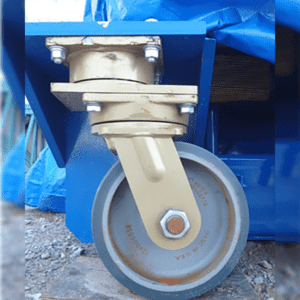

Caster Material and Wheel Size.

Caster Material and Wheel Size.Evaluate materials like nylon, polyurethane, rubber, or steel based on their durability and compatibility with the operating environment. For example, our 92A HPPT Poly tread resists heat buildup and can carry higher weight capacities, making it ideal for AGVs, Tuggers, and other higher-speed, higher-weight applications.

The caster wheel size should be proportionate to the load weight, as smaller caster wheels tend to distribute the load more evenly and provide better overall stability [1]. Additionally, a larger wheel means less effort to push it along, so you’ll need to weigh your priorities between maneuverability and longevity.

A rigid-type brake is typically best for high-traffic or heavier loads as it provides more stability than a swivel-type brake. In contrast, swivel brakes are easier to maneuver over uneven surfaces and take up less space. Additionally, some caster brakes require a lever to engage them. Others have built-in pads that allow for manual activation.

You can always try to optimize energy efficiency by selecting a caster with low rolling resistance to minimize friction between wheel surfaces and flooring.

You can always try to optimize energy efficiency by selecting a caster with low rolling resistance to minimize friction between wheel surfaces and flooring.

This approach helps optimize overall performance and extends a heavy duty caster’s service life while reducing power consumption during operation.

Enhancing the maneuverability of an automated guided vehicle (AGV) is based on the ease of directional changes and how well the caster accommodates various floor conditions. These factors greatly influence mobility, energy consumption, and overall AGV performance.

For example, casters with a large swivel radius facilitate smoother turning movements while reducing resistance. Lower rolling resistance is also achieved by choosing wheels made from materials like polyurethane or high-quality rubber. These wheels are designed to improve agility by minimizing friction between the wheel and the floor surface. This reduction in resistance ultimately results in lower energy consumption during operation and contributes to better overall performance for AGVs in their designated workspaces.

Swivel on Swivel Caster

Innovative caster designs, such as Twergo wheels or our swivel-on-swivel caster (SOS), are specifically designed to provide these types of benefits in AGV applications.

Specifically, Twergo wheels are designed with multiple wheelsets mounted on a single axle that work together to minimize friction during turns; this results in less energy consumption than traditional caster wheels.

Similarly, A swivel caster provides enhanced agility by allowing simultaneous rotation around two axes instead of one; this design reduces drag and allows smoother directional changes without excessive force or energy expenditure.

Selecting a caster with an appropriate wheel diameter can help reduce the energy needed to move it. This is achieved by ensuring the wheel’s contact patch with the ground surface is as small as possible. Other factors include:

In conclusion, selecting the appropriate caster for an AGV significantly impacts its overall performance, maneuverability, and power efficiency. A suitable caster design will optimize energy consumption while providing ease of movement in various operating conditions.

In addition, high-quality industrial casters can save money in the long run by minimizing repair and replacement costs. These casters are more durable than their cheaper counterparts and require less frequent maintenance and replacement.

If you need any help making the right choice, Caster Concepts is here to answer your questions. We pride ourselves on being able to help our customers find the best AGV caster solutions for both maneuverability and energy efficiency.

Contact us today. With our extensive experience and expertise in this field, we are confident that we can provide the caster that will meet your needs and exceed your expectations.

[1] Zepeda, R., Chan, F., & Sawatzky, B. (2016). The effect of caster wheel diameter and mass distribution on drag forces in manual wheelchairs. Journal of Rehabilitation Research & Development, 53(6).