The use of a wheel of some configuration on a standard or custom track is a very common application for an industrial caster and wheel product. When utilizing track wheels there are a few basic rules that you should follow no matter what the product application is.

1. Be sure there is a planned mismatch of the hardness of the track and the wheel. It is impossible to get the same hardness in the track and the wheel to minimize the wear of one or the other. One must decide that one or the other (wheel or track) is going to be the one that wears. Typically it is the wear of the wheel that is planned into the system. Certainly it is easier and generally cheaper to change out wheels rather than to change out tracks. Ideally it is suggested that the wheel be approximately 5 points softer on the Rockwell D scale than the track that it is running on to assure that the wear is minimized on the rail.

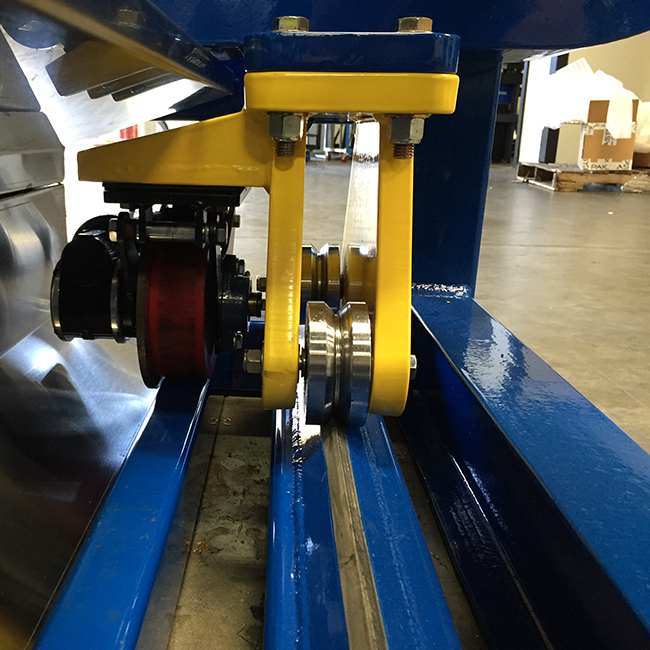

2. When a cart or platform of some sort is running on a track and there are four wheels that engage the track it is suggested that only one side of the cart be a flanged wheel while the other side of the cart be a flat face wheel. The track wheel being used must also capture the track on both side (Dual flanged or V-groove wheel) to assure the safety and stability of the cart. The reason for this is that most tracks are not laid in perfect alignment. There is variation of the width of the track. The cart must have the ability to adapt to the variation without becoming or the cart coming off the track.

Certainly the variation in track wheels is great as or greater than the variation of track configurations.

This configuration is certainly the most common configuration of a track wheel. The track rests with the U shaped surface of the wheel. Typically the width of the U will be slightly larger than the surface of the track. There are common track sizes that are manufactured in high volume that have standard classifications. It is very important that you communicate the track size to assure the proper track wheel. Material is generally cast iron or steel.

This configuration of wheel face captures the wheel on one side as opposed to both sides. This allows the cart to stabilized on the track while minimizing guidance and rolling effort. Wheel material is generally of cast iron or steel.

This is another common configuration of wheel that will run on a track. The V is machined into the face of the wheel at 90 degrees and a relief groove is placed at the base to assure that the weight is evenly distributed on the track. Configuration of the track should closely profile the surface of the wheel. This design is very strong and can carry very heavy loads.

Engineering input can very valuable when it comes to designing/selecting the proper wheel and track configuration. Caster Concepts, Inc. engineering group have extensive experience in track wheel applications. Call and get expert input to minimize the cost and assure down time is avoided.