A good industrial caster will offer a multitude of attributes and benefits that will keep your carts. And your manufacturing operation – rolling forward. But if manoeuvrability tops the list of your industrial caster must-haves, it’s worth considering a heavy-duty caster equipped with a swivel lock.

Industrial caster applications involving swivel caster with lock generally feature a combination of the straight-line stability you expect from a quality heavy-duty caster, with the added benefit of locking individual casters into a rigid state to support specific tasks.

Generally speaking, these locks are permanent add-ons that do their job uncomplicated and straightforwardly. However, our engineers have worked to create some variations on the theme depending on whether your application calls for a swivel-lock that puts a premium on compatibility, durability, strength – or a combination. Let’s explore this in greater detail:

The standard swivel lock uses a spring/ plunger design housed in a barrel welded to the industrial caster top plate. The pin engagement notches are located at all four 90-degree intervals. So, they run parallel and perpendicular to the heavy-duty caster legs. The spring and plunger are actuated by pulling and rotating the plunger to engage with a notch on the swivel barrel lock.

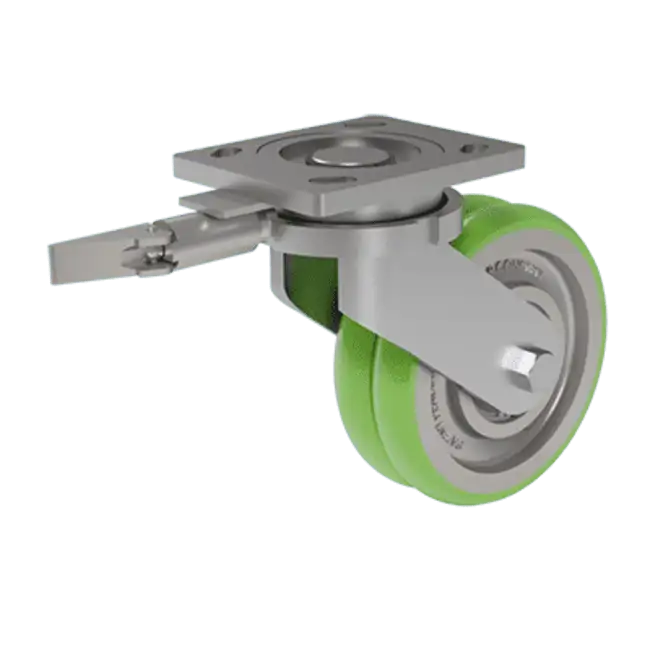

The demountable swivel lock is the perfect component for any industrial caster application that requires adaptability. However, this type of swivel lock works much like the standard lock. It varies in that the barrel is welded to a separate plate with the same mounting pattern as the caster top plate. Depending on the application, this component allows the lock to be removed and swapped with other components.

The passive swivel lock is at the cutting edge when manoeuvrability is required for your heavy-duty caster application. Because of its passive nature, the safety will keep the caster in one position until a side load is applied, allowing it to sway freely again. This lock is permanently engaged and uses a plunger with round swivel section notches and tips that reduce the force needed to disengage the lock. Since this locking mechanism remains permanently employed, these are the ideal locks for an application requiring straight-line stability.

The strength of this lock is paramount when dealing with heavy-duty applications. As such, the vertical swivel lock variant is the ideal component. This heavy-duty lock differs from most locks in that it is mounted perpendicular to the direction of motion. The plunger mechanism on this lock engages holes drilled into the top half of the industrial caster swivel section. The vertical swivel is ideal for heavy-duty applications because complete engagement of the pin with the hole makes for a much stronger lock, capable of handling larger load capacities.

Here at Caster Concepts, we have engineered and can produce various locks for your application. And even custom-design to your unique specifications. Design the exact caster for your needs on our Custom Configurator. Including the options you need, and download a 3D model. For additional information or a quote, don’t hesitate to contact us at customercentral@casterconcepts.com or call 517-680-7950.