One question we often get from manufacturing companies that tow trains of carts around their facility is, “Can you make a central swivel locking system for our carts?” There aren’t many of these solutions out there, and now that you mention it, we do happen to have one.

A central swivel lock system is a system that allows the user to engage two or four swivel locks with one mechanism – sometimes a foot pedal, and sometimes it is attached to a tow bar.

With this system, you don’t have to maneuver the cart to find the brake pedal, which can swivel around with your casters. It is in one place, letting you have total lock brakes on all casters.

When the locks are engaged, the swivel action of the wheels is fixed in a straight or locked position. This makes the casters work as rigid casters.

When the swivel locks are off, the casters are full swivel casters. You would use this system in a manufacturing situation where a cart gets tugged or towed around a facility but then needs to rotate upon itself when placed at the assembly line or cell.

The most common setup is for the swivel locks to be engaged when the tow bar is down, and the swivel locks engage a single notch on the rear casters. This makes the casters act as rigid casters and allows the cart to track behind the towing vehicle. If the casters were left as all four swivel casters, the cart would not track and would become a severe safety issue if towed.

RELATED: How do I keep my cart from fishtailing around corners?

When the cart is delivered to its final spot, the tow bar is raised, disengaging the swivel locks on the rear casters. This allows the cart to have full maneuverability. It can move straight, sideways, and spin on itself to allow operators the best position to pull parts.

Many cart manufacturers offer a parent/child cart setup where the parent cart has two rigid casters or fixed wheels and then two swivel casters or two wheels on a steering system—the child cart then nests inside the parent cart to be towed around the facility. The child carts are equipped with four swivel casters to allow full maneuverability. While this system works well, you are essentially adding another set of carts into the manufacturing process with the parent carts.

With a central swivel lock system, you can eliminate the parent cart and have one coach that can change between four or two swivel and two rigid casters while towing.

While the swivel caster with lock utilized in the central swivel lock systems tends to be custom, we can reverse engineer any caster and provide you with a more durable or ergonomic option. We often see this issue in the field where the swivel lock system works great, but the casters used are subpar. Due to our manufacturing capabilities and short lead times, we can easily reverse-engineer the current casters and provide an upgraded caster for your operation.

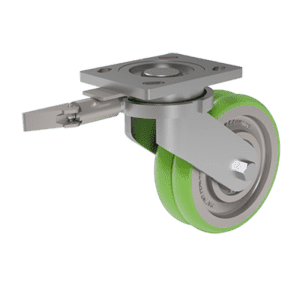

Brakes and Swivel Locks are common add-ons for heavy duty industrial casters, whether for two or four wheels:

Foot Swivel Lock

Both brakes and swivel locks also add safety benefits:

Caster Concepts is here to help. Our sales and engineering professionals can guide you through the process by thoroughly listening to your needs, understanding your requirements, and delivering a product that meets and exceeds your expectations.