Innovation in modular construction extends beyond the buildings themselves. It also includes the tools that make efficient manufacturing possible. One of the biggest challenges facing modular manufacturers is how to move large, heavy modules safely and efficiently through their facilities. Traditional solutions such as fixed dollies, oversized carts, or forklifts don’t have the heavy duty capacity for success — creating bottlenecks, wasting space, and adding costly downtime.

What are Custom Modular Skates?

What are Custom Modular Skates?

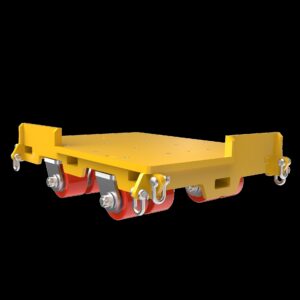

Custom Modular Skates are heavy-duty, dual-wheel mobility systems engineered to move modular building sections through manufacturing facilities.

Dual-wheel design that distributes weight across a greater surface area

Lower profile for increased stability

Built-to-spec—designed around the module size, subframe, and facility layout

These skates are not off-the-shelf products. They are designed and manufactured at our headquarters in Albion, Michigan. Each caster skate is built around the modular manufacturer’s exact needs, module dimensions, and facility layout. The result is a solution that makes moving modules easier, faster, and safer.

Multiple configurations are available to suit different applications, including 360-degree swivel assemblies, fixed-track systems, and hybrid designs that combine both features.

Each skate is adjustable to fit modules from 10′ x 10′ up to 60′ x 100′, providing exceptional flexibility as module designs change. Mechanical linking features allow multiple skates to connect, ensuring the skates—not the module structure—absorb the load and movement stress.

A recent project with Roc Modular demonstrates this innovation. Their modules required greater load stability than standard skates could provide. Our team designed an elongated top plate to distribute weight evenly across the subframe, creating a stable, bolt-on solution. The skates integrated seamlessly into Roc Modular’s production line and improved both safety and efficiency.

With Custom Modular Skates, manufacturers gain:

Improved maneuverability

Superior stability under extreme loads

A dramatic reduction in caster replacement costs

Optimized workflow without expanding facility footprint

As seen with Roc Modular, these improvements translate directly into faster throughput, safer operations, lower overhead, and better use of available space.

Unlike dollies or carts that force manufacturers to adapt, these skates are built specifically for each operation. By designing backward from the customer’s needs, Caster Concepts’ engineers can design skates that provide unmatched control, adaptability, and long-term durability. As module designs evolve, our expertise in skate designs evolves also, making this a fully custom, future-ready solution for the industry.