In the caster industry, there can be a lot of confusing and unfamiliar terminology. Especially if these terms aren’t something you deal with daily. My hope is to help clear up several of those confusing words, phrases, and terms in a series of blogs about caster terminology. You can find this terminology commonplace on caster websites, catalogs, or even in a discussion with a sales representative.

This blog will be the first in a series and will cover the caster rig or assembly, the second will be the caster wheel, and the third will be on terminology regarding caster accessories.

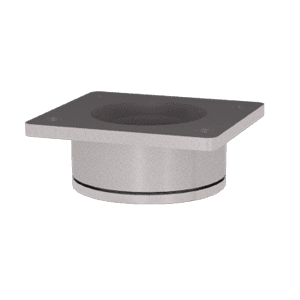

Let’s begin by defining what the caster rig or assembly is. Rig and assembly are interchangeable words that refer to the metal components that house a wheel, or in some cases wheels, of a caster. When the rig has not yet been outfitted with a wheel it will look like what some may say is a bracket. The rig can be ordered in 2 different styles. It can either have a swivel section or be rigid.

Swivel section

A swivel caster is almost self-explanatory in that it allows the wheel to turn 360 degrees. The term rigid may also be substituted for stationary, and that’s because the wheel will not be able to swivel and turn from side to side. That’s because there is no swivel section in a rigid caster so it doesn’t turn. Therefore, a rigid caster will only be able to move in a straight line forward or backward.

Top plate configuration

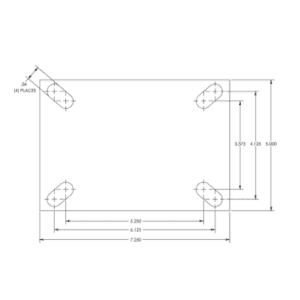

At the very top of the rig is the top plate. A top plate may also be referred to as a mounting plate. This plate is used to either weld or bolt the caster to the application it will be used in. Depending on the weight capacity needed per caster — and the size of the wheel that will be going into the rig — this top plate size can range from 4.5”x 4” up to a plate size of 14”x 14” in standard products at Caster Concepts.

Each top plate size then has its own standard bolt-hole pattern. The bolt-hole pattern is what determines where the bolts are going to be placed for mounting your caster. This pattern is measured from center to center of each bolt hole to determine the size of the pattern. These patterns can also be cut with variance in the shape of an oval to allow for different-sized bolt-hole patterns on a single plate.

The final term of a caster rig that I will mention is the yoke. This is attached to the bottom of each swivel caster’s top plate, and it matches up with the bottom half of the swivel sections raceway where the bearings are housed. The yoke allows the caster to swivel. This will be covered more in the Accessories part of this trilogy, but a yoke may also come notched if you have a need to also stop a swivel caster from swiveling.

This final term overlaps with the caster rig and the wheel, so I have chosen to place it here before moving on to the wheel portion of this trilogy. This is about the overall height — or OAH — of your caster. This is important if you are trying to meet an exact height, match up new casters with existing ones, or make sure to not exceed a certain height requirement with your application.

In many applications, there are constraints as to the size of the caster that will fit. This overall height will also have a direct impact on the load capacity of your caster because the larger the rig and the larger the wheel, the higher your load capacity can be. To find a caster’s overall height you measure from the top of the top plate all the way to the bottom of the wheel where it will contact the floor.