We’re seeing loaded carts in facilities weighing as much as 2,000 and 3,000 lbs. The ergonomic casters used on these carts are one of the most important — and most overlooked — parts of the safety equation.

As ergonomic casters innovators, Caster Concepts is challenging the widely accepted norm that a cartload must be 1,200 lbs. or less for one person to move safely. Better caster technology designed to significantly lower push force involves factors including rollability, swivel sections, wheel bearings, and load considerations. Improving these allows companies to address pain points and reduce total capital expenditure while keeping employees safe and happy.

Ergonomic casters are designed to create less friction with the ground. This benefit can significantly reduce the force exerted to move and turn a cart or dollie, resulting in reduced risk of injury and comp costs while potentially increasing productivity.

|

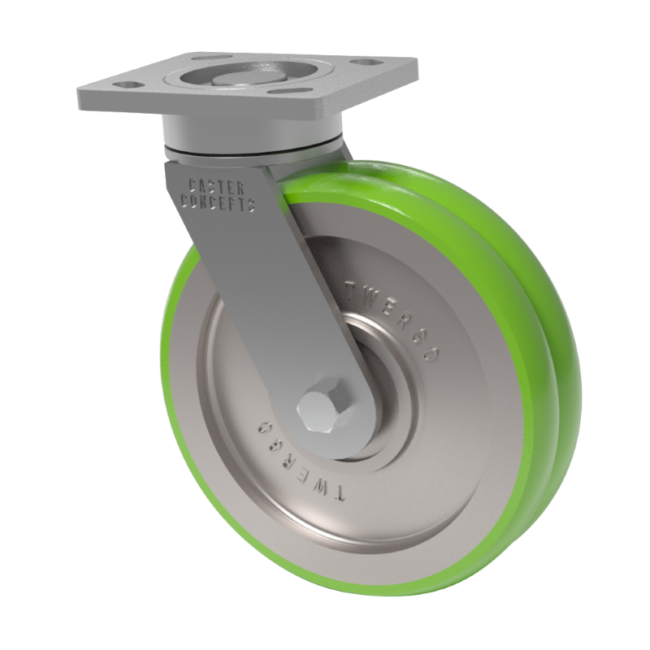

Our TWERGO® ergonomic caster wheel has earned an industry-first, third-party seal of approval. This certification confirms that TWERGO industrial casters have been tested and validated to reduce push forces by over 55% compared to traditional balloon casters. This allows cart operators to maintain a push force below 40 lbs. while moving over 2,000 lbs.

Depending on load capacity, TWERGO is also available as a TWERGO® Lite caster and the TWERGO® XTREME. |

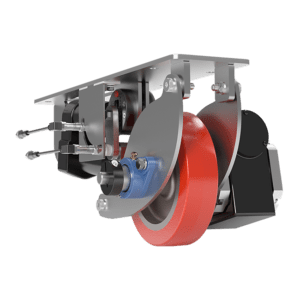

Swivel on Swivel Caster |

Our Swivel on Swivel (SoS) casters are innovatively designed so the 2nd swivel section transfers energy to the 1st swivel section. Utilizing two swivel sections that feature precision ball bearings aids in rotation and reduces the amount of shifting that occurs. This is extremely beneficial when maneuvering a cart, especially in tight areas. Because these Swivel on Swivel casters reduce the force needed to turn, operator fatigue and injuries are minimized. |

55 Series Twergo Caster |

ERGOXCEL™ features a round balloon tread that reduces the footprint that comes in contact with the floor, resulting in less friction and reduced force compared to a traditional flat tread wheel. The balloon tread also helps to push away debris rather than trapping it in the wheel.

Tread polyurethane formulations such as our ErgoTread formulation are another beneficial way to return energy and help reduce the force exerted to keep rolling.

Drive Caster® |

The Drive Caster® is a first-of-its-kind, motorized caster designed to move tons quickly and efficiently. With Drive Caster, a single operator can easily start, maneuver, and stop a load of up to 2,000 lbs. by using a control panel and tank steering. The Drive Caster has the flexibility to integrate into a variety of applications and configurations to increase load capacity. |  |

Designed for a variety of uses, including AGVs, Tuggers, and other higher-speed applications as well as carts and dollies that need to move greater weights while reducing the push force required to keep them moving.

Caster Concepts has a wide variety of caster options. Many of these not only improve function – but also provide safety and add longevity to the product. When considering safety options, the most common consideration would be caster locks, caster brakes, toe guards, and reinforced legs. Options that extend the life of a caster are primarily options that seal the bearing of the caster to prevent contamination of the precision parts.

Other options include threaded zerks for when an application is difficult and high level of maintenance is required and track brush wipers that keep debris from stopping movement or damaging a wheel. These options can be added at the time of manufacturing or after the caster is fully assembled.