The correct caster top plate configuration can be basic or complex, depending on your application.

The correct caster top plate configuration can be basic or complex, depending on your application.

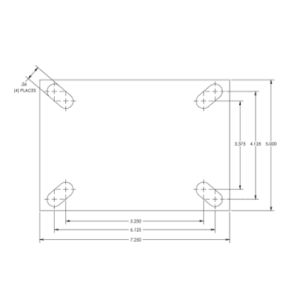

The first step in choosing the correct top plate size is to measure the bolt-hole spacing.

Slotted bolt hole spacing will read something like 2.625” x 3.625” slotted to 3.0” x 3.0.” What this means is that your measurements need to fall between the parameters listed. One measurement should fall between 2.625”-3” and the other between 3”-3.625.” If the top plates are not slotted, they might have fixed holes such as 7” x 7” in which you will need to have the exact same dimensions.

There are times when top plates must sit in a designated slot. This could be a quick change bracket that a caster will slide into a mounting bracket for easy replacement. The cart or unit could also have a pocket that will only allow a specific size top plate to mount into.

In the event that the bolt-hole spacing or top plate size is not in the standard product offering. Please contact us. Custom casters are an everyday event for us at Caster Concepts. We have helped customize top plate configurations for our customers to fit an exact top plate size and bolt-hole spacing. This includes and is not limited to, metric sizes and multiple bolt holes in one top plate to standardize with one caster.